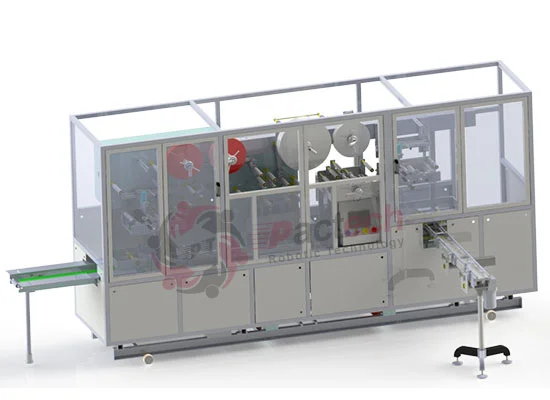

Toilet Soap Wrapping Machine

Standard Machine product range PRODUCT SIZE (all dimensions in mm)

| lenght | height | width |

|---|---|---|

| L Min 65 | H Min 13 | W Min 35 |

| L Max 175 | H Max 45 | W Max 65 |

Customization considered as per customer request

Toilet Soap Wrapping Machine

Toilet Soap Wrapping Machine

Toilet Soap Wrapping Machine

Toilet Soap Wrapping Machine